CHMER EZ Series CM545Z Die Sinker EDM

CHMER EZ Series CM545Z Die Sinker EDM

Description

The CHMER ZNC Series Sinker EDMs offer an affordable solution for many EDM applications. If you are making single cavity molds or short run EDM production, the ZNC EDM might be the solution. The ZNC Series include CM323Z, CM434Z, CM545Z and CM655Z.

Unlike a manual die sinker, the ZNC offers the conversational EZ control. This conversational control has the built-in digital cutting technology to easily select the correct cutting technology after answering the questions: electrode type, workpiece material, electrode shape and desired surface finish. The ZNC control will then automatically select the recommended cutting technology. This technology can be used or modified to fit your application. The ZNC model includes scales and DROs on all three axes for true position and Z depth control.

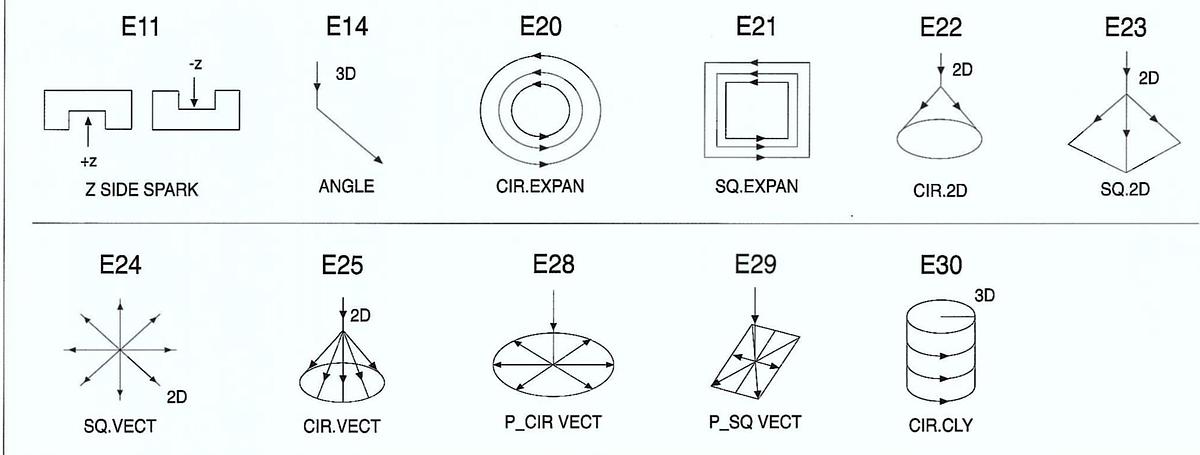

In addition, with the optional Loran orbitor, you can program a cavity and activate the Loran, based on the Z depth, all from the CHMER ZNC control. The Loran has +/- 5mm of travel so you can expand an opening in square, circular, vector or many other modes. You can even insert threads into hard metal using threaded electrodes and circular orbits. The Loran will help to improve surface finishes, reduce electrode sizes, increase cutting speed with the optional Loran orbitor.

Power supplies from 50-300 amps.

Installation and On-site Training are included.

Options:

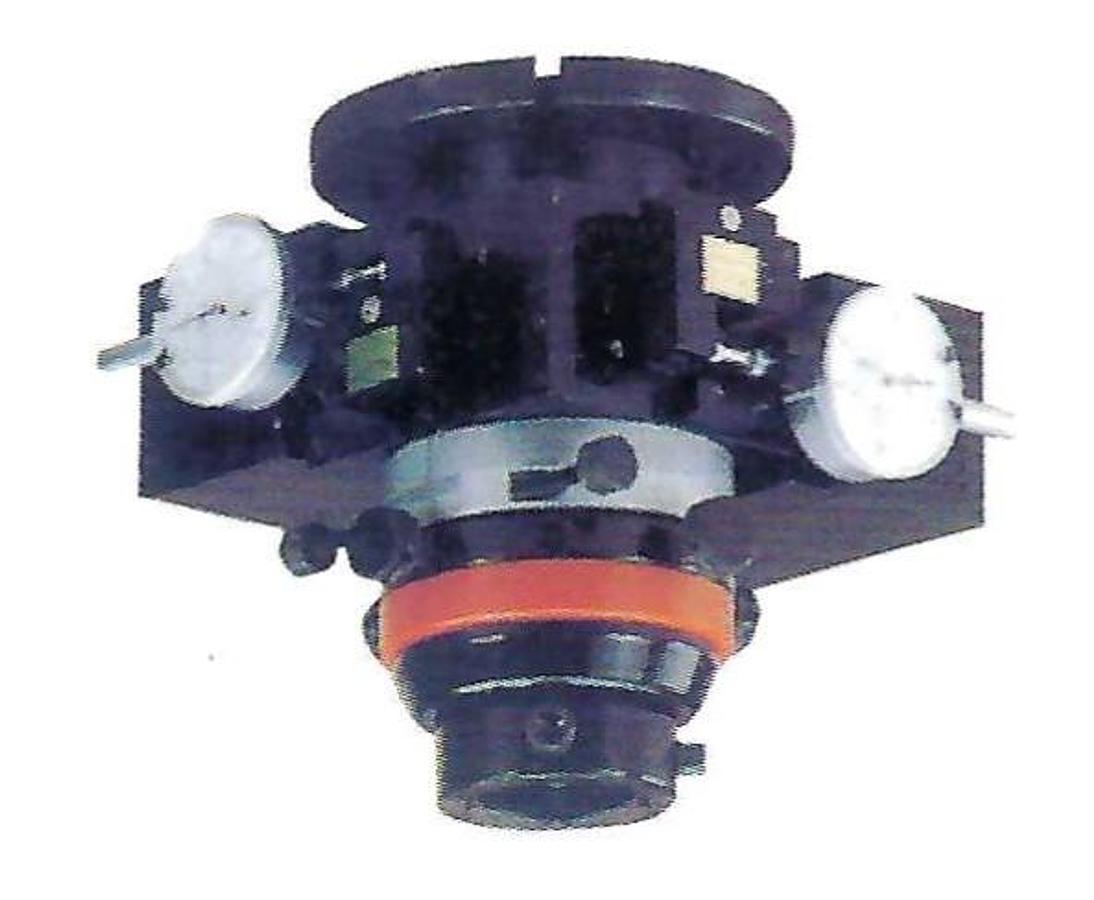

- Loran Orbitor (picture attached)

- 3R Manual Macro Chuck

- EROWA Manual Chuck

- 25 amp Booster to 75 amps total

- Halon Fire Suppressor

- Fire Trace Fire Suppressor

- Auto Lubrication

- Password Protection

Specifications

| Manufacturer | CHMER EDM of Taiwan |

| Model | CM545Z ZNC Series Die Sinker EDM |

| Year | 2025 |

| Condition | New |

| Stock Number | CM545Z- |

| Travels (XYZ): | 500 x 400 x 500 mm / 19.7" x 15.7" x 19.7" |

| Work table size (WxD): | 800 x 500 mm / 31.5" x 19.7" |

| Work tank size (WxDxH): | 1250 x 700 x 500 mm / 49.2" x 27.6" x 19.7" |

| Ram platen to work table: | 205 - 705 mm / 8.1" - 27.8" |

| Max. electrode weight (w/o OB): | 300 kg / 660 lbs. |

| Outside dimensions (WxDxH): | 1600 x 1600 x 2570 mm / 63" x 63" x 101.2" |

| Machine weight: | 3200 kg / 7040 lbs. |

| U,V axis travel (OB) | +/- 5 |

| Max. electrode weight (w/OB) | 15 kg / 33 lbs. |

| Max. workpiece weight | 1500 kg / 3,00 lbs. |